Oil mist eliminator with blower

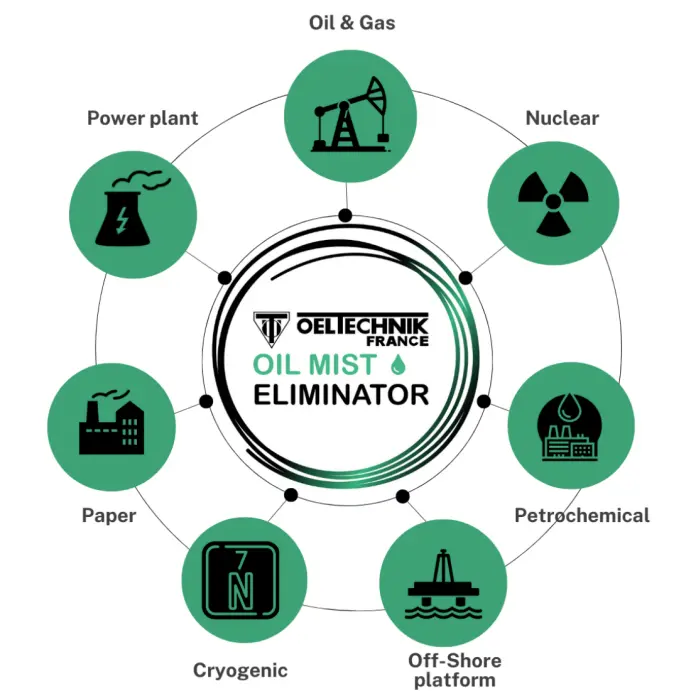

Use an oil mist eliminator / oil mist separator to preserve the planet and avoid contamination of oil by aerosol. Oil mist eliminators act as filters during the operation of lubricating oil systems like rotating machines, centrifugal pumps and turbines. The rotating equipment requires an oil injection system for good lubrication of the various bearings in that equipment.

Use an oil mist eliminator / oil mist separator to preserve the planet and avoid contamination of oil by aerosol. Oil mist eliminators act as filters during the operation of lubricating oil systems like rotating machines, centrifugal pumps and turbines. The rotating equipment requires an oil injection system for good lubrication of the various bearings in that equipment.

A mist eliminator must be connected to this system to avoid leaks. During the operation of these machines, the friction of the bearings will cause the temperature to rise and heats the lubricating oil that comes back into the tank. This temperature elevation causes a state change and creates an oil mist in the tank.

Without mist eliminators, the air containing oil particles would be rejected in the atmosphere. It could cause some damages on the employees and do some pollution for the planet.

When equipped with an oil mist separator, the oil mist pass through the cartridges where the coalescence operates : the oil is separated from the air. The clean air is exhausted to the atmosphere and the oil returns to the tank by gravity.

Learn more about the oil mist eliminator with blower

Static oil mist separator / Breather

The air in the tank goes through the oil mist eliminator due to the small pressure available on the system. The air goes naturally through the cartridges, where the coalescer process is operating. The oil is separated from the air and returns to the tank by gravity. The air is clean and goes out.

The air in the tank goes through the oil mist eliminator due to the small pressure available on the system. The air goes naturally through the cartridges, where the coalescer process is operating. The oil is separated from the air and returns to the tank by gravity. The air is clean and goes out.

This type of oil mist separator does not need any power supply and can be installed anywhere you need to filter the oil mist. It can be used in industrial environment, in outdoor installations and can be compatible with explosive area (ATEX compliant).

Learn more about the static oil mist separator

Many options ara available such as :

- Pressure gauge

- Stainless steel or carbon steel construction

- ATEX : can be installed in explosive area

- Other specifications on request