Our different types of Oil Mist Eliminator products

Use an oil mist separator with a blower to create a depressurization in the oil tank. This improves the tightness of your oil system by sucking the air with a side channel blower (or a centrifugal fan for specific executions). You can adjust the depression value using a bypass valve and an air filter, or using a bypass valve in a recirculator way.

Use a static oil mist separator (also called a breather) on any tank or system that needs an oil mist to be filtered before letting the air goes out through an event connection. It does not use any mecanical suction system and the air pass naturally though the cartridge. This system is designed to work with small flow rates (max 200 m3/h) and it has a low pressure drop to avoid your system to be over-pressurized.

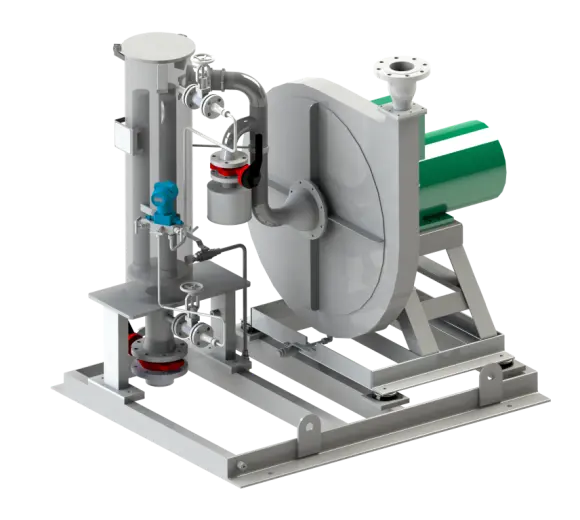

Oil mist eliminator on skid

ADCO TECNIMONT

- 575 Nm3/h

- DN 100 inlet/outlet

- 2 side channel blowers

- Painted stainless steel 316/316L

- Isolating gate valves

- Knitmesh pre-filter

- Equipped with a differential pressure transmitter and manifolds

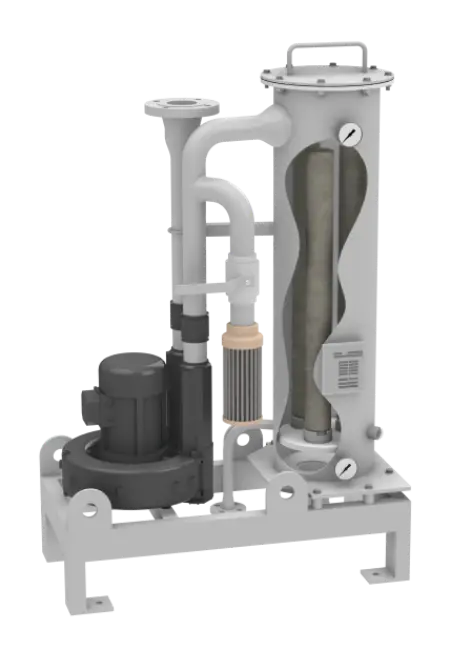

Oil mist eliminator with centrifugal fan

CIDADE DE PARATY

- FPSO, Offshore application

- 100 Nm3/h

- DN 100 inlet/outlet

- Centrifugal fan in stainless steel

- Stainless steel 316L

- Equipped with a differential pressure transmitter and 5 ways manifold

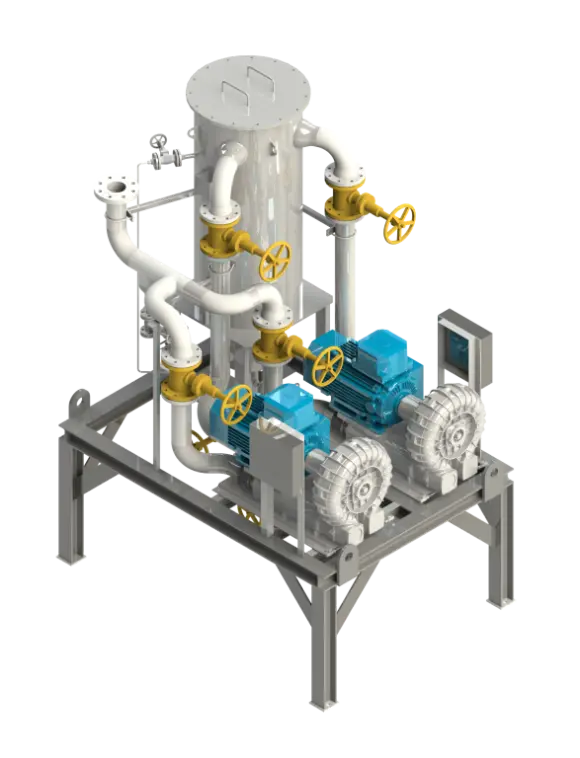

Oil mist eliminator with twin blowers

ADCO TECNIMONT

- 200 Nm3/h

- DN 100 inlet/outlet

- 2 side channel blowers

- Painted stainless steel 316/316L

- Isolating gate valves

- Knitmesh pre-filter

- Equipped with a differential pressure transmitter and 5 ways manifold

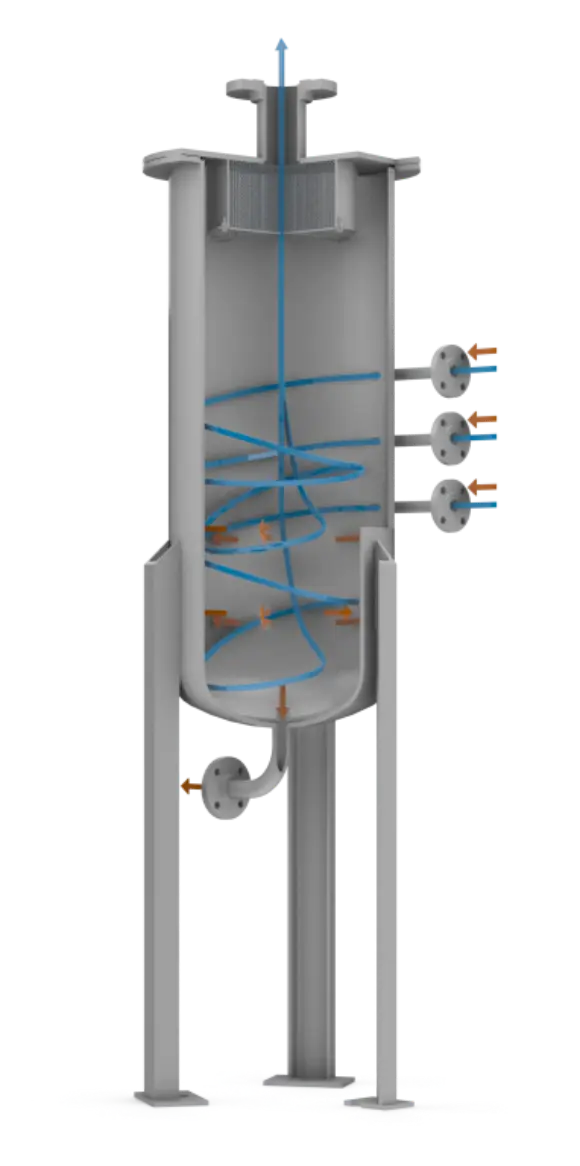

Cyclonic oil mist separator with 3 pressurized inlets and a knitmesh filter

SPIE

- Replacement of an existing OME

- Dimensions according to customer requirement

- 3 pressurized inlets

- Cyclonic type with a knitmesh filter

- Painted carbon steel

Cyclonic vent - Custom execution

BUZIOS 7 – MERO 3

- Cyclonic vent

- DN 250 body

- DN 50 inlet/outlet

- Design pressure 0.1 bar g

- Design temperature 200 °C

- Material and mechanical calculation according to ASME VIII Div .1

- ATEX Zone 2, Group IIB T3 (Ex II 3G Exh IIB T3)

- Painted stainless steel 316L

Oil mist eliminator with integrated breather safety valve

KAOMBO – CENTRICA

- Flow rate 100 Nm3/h

- Efficiency 99.5%

- DN 80 inlet/outlet

- Breather safety valve inside

- Pressure setting 35 mbar

- Stainless steel 316/316L