Working principle of a Static Oil Mist Separator

Oeltechnik France Static Oil Mist Eliminator is necessary when using different devices that require lubrication. To Lubricate this machinery, it has to work with an oil system. This system must be combined with a demister. If not, some of that oil will contaminate the atmosphere in the form of a mist. Why an oil mist? Because while the oil is running the heat will increase and it will create an oil mist in the tank.

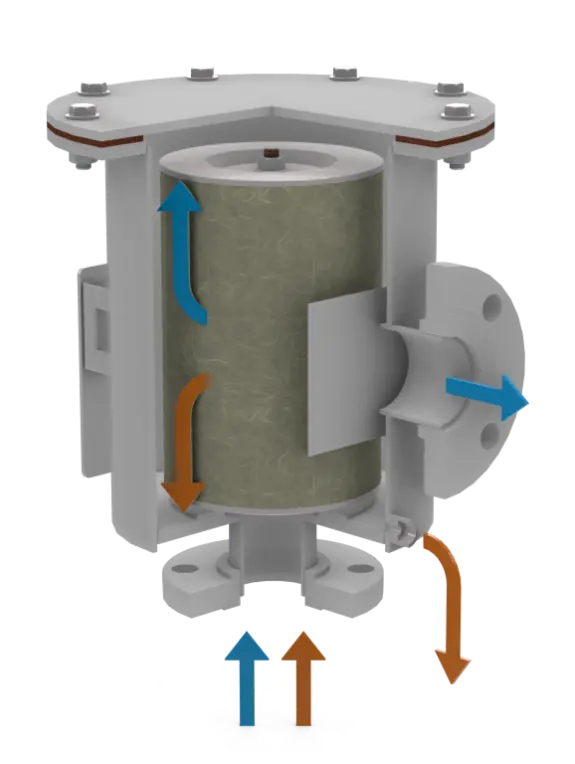

The Oil Mist Separator will act as a filter and capture the oil present in the mist. With the coalescing process of the cartridges, the oil will accumulate in form of droplets bigger and bigger and return to the oil tank.

Which function assure a Static Oil Mist Eliminator

With Static Oil Mist Separator, companies can :

Avoid contaminated atmosphere from lubricating oil used in the oil system

Keeps employees healthy

Ensure the sustainability of the workshop by preventing alteration to other machines

Comply with environmental requirements from different countries

Save oil that would go into the atmosphere and put it back in the tank, it is a non-negligible cost saving.

Differences between Static Oil Mist Separators and blower assisted Oil Mist Separators

Static Oil Mist Eliminator differs from Demister with a blower. There is no need to create a vacuum in the oil tank. Static Oil Mist Separators are useful where the level of pressure can be positive. It helps to avoid overpressure in the tank, which could form while accumulation of oil mist in it.

Our Static Oil Mist Separator has an operating capacity of up to 200 m3/h. Beyond this value, it will need to couple the device with a blower to make it work in optimal condition and not cause damage to coupled machines.

Our expertise for your needs

Our Static Oil Mist Separators will be adapted to your equipment and the available space. The only need here is to list your conditions when you send a price inquiry, and our design office will take care of producing it compliant with your place and requirement.

Options :

- Stainless Steel or Carbon Steel

- Vacuum-assisted oil mist eliminators

- ATEX, NEMA certification

- Manometers, pressure transmitters

- Tamis knitmesh ( Oil demister pads)

Applications :

- Compressors

- Gas Turbine

- Hydro Turbine & Solar Turbines

- Gas and diesel engines

- Application with positive pressure

- Hydraulic Gear Boxes

Why to use an oil mist separator ?

A static oil mist separator, also known as a mist eliminator or demister, is a device that is used to remove droplets of oil from a gas stream in lubrication systems. When lubricating oil is used in machines, it is often atomized into small droplets, which can then be carried away by the air and released into the atmosphere. These droplets of oil can be harmful to the environment and can also cause operational problems in the lubrication system. A static oil mist separator is designed to capture these droplets of oil and remove them from the air stream, helping to keep the lubrication system and the environment clean.

How work the static mist separators ?

Static oil mist separators work by using a series or only one cartridge that are designed to capture droplets of oil as they pass through the device. The droplets are then collected and returned to the lubrication system, while the purified air is allowed to pass through.

One of the main applications of static oil mist separators is in lubrication systems for large machines such as turbines, compressors, and gearboxes. These machines rely on lubricating oil to keep them running smoothly, and the oil is often atomized into small droplets as it is used. These droplets can be carried away by the air and released into the atmosphere, which can cause environmental problems. A static oil mist separator is used to capture these droplets of oil and remove them from the air stream, helping to keep the environment clean and the lubrication system operating efficiently.

Static oil mist separators are also used in the breathing systems of lubrication systems. Breather systems are designed to allow air to enter and exit the lubrication system as the oil level changes. This helps to prevent the build-up of pressure or vacuum in the system, which can cause operational problems. However, the air that enters and exits the system can also carry droplets of oil with it, which can be harmful to the environment. A static oil mist separator is used in the breathing system to capture these droplets of oil and remove them from the air stream, helping to keep the environment clean and the lubrication system operating efficiently.

How to choose your oil mist breather ?

The design of static oil mist separators is an important aspect to consider for the efficiency of the device. The pressure drop across the device is one of the main factors to consider. The pressure drop is the difference in pressure between the inlet and outlet of the mist separator. A high pressure drop can result in a decrease in the efficiency of the separator or the compressor and increase the energy consumption. Therefore, it is important to choose a design that has a low pressure drop to ensure the efficient operation of the system.

Another important aspect to consider is the droplet size that the breather can effectively remove. The size of the droplets that the mist separator can remove is known as the cut-point. The cut-point is determined by the design of the oil mist separator, and the selection of the appropriate breather for a specific application will depend on the droplet size that needs to be removed.

In terms of materials of construction, oil mist separators are typically made of stainless steel, or carbon steel. The choice of material will depend on the chemical properties of the oil and the operating conditions of the system. Stainless steel is suitable for most lubricating oils and is commonly used in industrial applications.

In addition to design and materials of construction, the maintenance and cleaning of the mist separator is important to ensure its efficiency and longevity. It should be inspected and cleaned regularly to remove any accumulated oil or debris.