In today's industrial landscape, safety and compliance are of paramount importance. One area where safety is non-negotiable is in environments where explosive atmospheres are a constant risk. To mitigate these risks, many industries rely on Zone 1 ATEX components. These specialized components are designed to ensure the safety of workers and protect valuable equipment. In this article, we will delve into the significance of Zone 1 ATEX components, particularly the role of oil mist eliminators, in various industries. We will also explore the potential risks associated with not having these safety measures in place.

Understanding Zone 1 ATEX Components

Before we discuss the importance of Zone 1 ATEX components, let's break down what these components are and why they are essential. ATEX (Atmosphères Explosibles) is a directive that was introduced by the European Union to regulate equipment and protective systems for use in potentially explosive atmospheres. These atmospheres may contain gases, vapors, mists, or dust that can ignite under certain conditions.

Zone 1, in the context of ATEX, refers to areas where explosive gases, vapors, or mists are likely to occur occasionally during normal operation. Industries such as petrochemical, pharmaceutical, and manufacturing often operate in Zone 1 environments. In these hazardous zones, the risk of explosion is a constant concern, making the use of specialized equipment and components crucial.

The Role of Zone 1 ATEX Components

Zone 1 ATEX components are designed to operate safely in explosive atmospheres by preventing and controlling potential sources of ignition. These components are constructed to meet strict standards and regulations to ensure they can withstand the harsh conditions of Zone 1 environments. Here are some of the key roles of Zone 1 ATEX components:

- Ignition Prevention: Zone 1 ATEX components are engineered to prevent any sparking or overheating that could ignite flammable gases, vapors, or mists. They are built to be intrinsically safe, reducing the risk of ignition.

- Equipment Protection: In addition to safeguarding human life, Zone 1 ATEX components also protect valuable industrial equipment from potential explosions. This helps industries avoid costly downtime, repairs, and production losses.

- Compliance: Adherence to ATEX regulations is mandatory in many industries. Using Zone 1 ATEX components ensures compliance with safety standards, reducing legal and regulatory risks.

- Worker Safety: The primary concern in hazardous environments is the safety of workers. Zone 1 ATEX components play a crucial role in minimizing risks to personnel working in these areas.

The Importance of Oil Mist Eliminators in Zone 1 Environments

One critical component often used in Zone 1 environments is the oil mist eliminator. Oil mist eliminators are specifically designed to remove oil and particulate matter from industrial processes. In environments where explosive atmospheres are a concern, these devices serve multiple purposes, making them indispensable. Let's explore the significance of oil mist eliminators in these settings:

- Explosion Prevention: Oil mist eliminators play a vital role in preventing explosions in industries that use oils and lubricants. The elimination of oil mist reduces the risk of flammable aerosols forming in the air.

- Air Quality: Oil mist eliminators contribute to better air quality in industrial settings. Removing oil and particulates from the air not only mitigates explosion risks but also enhances the working conditions for employees.

- Environmental Impact: Many industrial processes release oil mist into the atmosphere, which can have a significant environmental impact. Oil mist eliminators help reduce air pollution and support sustainability efforts.

- Equipment Maintenance: Oil mist can settle on equipment and machinery, causing premature wear and tear. By eliminating oil mist, these devices extend the lifespan of industrial equipment and reduce maintenance costs.

- Improved Efficiency: Clean air and well-maintained equipment result in more efficient industrial processes. Oil mist eliminators contribute to increased productivity and reduced downtime.

Our Oil Mist Eliminator compatible with the Zone 1 ATEX

We are manfucaturing oil mist separators since many years for different sectors of the industry and we are able to deliver a product that is certified with the Zone 1 ATEX.

- Stainless steel or carbon steel parts

- plastic parts

- electrical conductivity

- Fan and motor

- Instruments

Stainless or Carbon steel parts

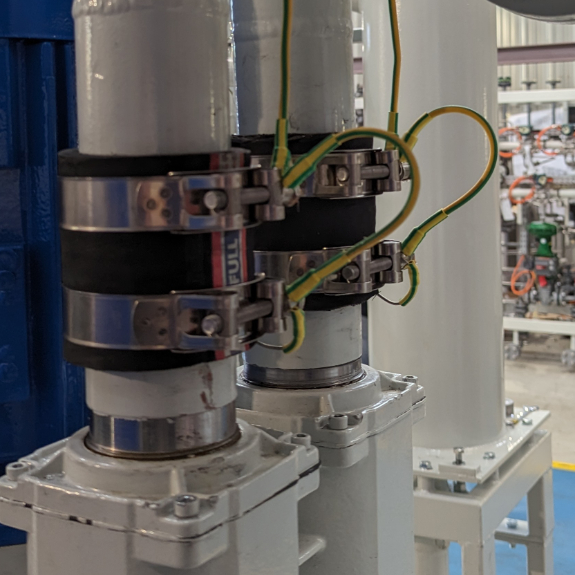

Where the Zone 1 ATEX can not be applied using standard plastic parts, we use some specific high quality parts in stainless steel or carbon steel to ensure the conductivity and the compliance of the oil mist eliminator

Electrical conducivity

The Zone 1 ATEX requires a specific conductivity for all parts, including the plastic parts that needs to be especially designed to be compliant. We are sourcing the parts from partners where the Zone 1 ATEX is a requirement that ensure the correct conductivity of all parts. We also add earthing conductiviy with additionnal electrical connections.

ATEX Instruments

Each part of the oil mist separator is compliant with the Zone 1 ATEX, including the instruments like the manometers. They are compliant and purchased according to the customer needs (diameter, units, etc).

Fan and motor

We are able to deliver the oil mist eliminator with a side channel blower certified for ATEX Zone 1 and make it adaptable with the needs of a custom motor according to the custom specifications.

ATEX Marking

To ensure the security and the compliance of the Zone 1 ATEX of our equipement, we are adding the needed marking and name plates on the body of the oil demister. A file submission is done through the authorized organizations.

In industries where explosive atmospheres are a constant concern, the use of Zone 1 ATEX components is non-negotiable. These specialized components, such as oil mist eliminators, play a crucial role in preventing ignition sources, protecting equipment, and ensuring the safety of workers. Neglecting safety measures in these environments can lead to catastrophic consequences, including explosions, legal actions, and environmental harm.

The oil mist eliminator, specifically, is a key component that not only reduces explosion risks but also contributes to cleaner air, better equipment maintenance, improved efficiency, and environmental sustainability. It is a testament to the multifaceted benefits of investing in Zone 1 ATEX components, not only as a safety measure but also as a means to enhance overall industrial operations.

In conclusion, the importance of Zone 1 ATEX components cannot be overstated. They are the cornerstone of safety and compliance in industries operating in hazardous environments. The use of oil mist eliminators, in particular, underscores the commitment to safety, efficiency, and environmental responsibility. By prioritizing these components, industries can ensure the well-being of their workers, protect their investments, and foster sustainable operations in an ever-demanding industrial landscape.